Before a food item even reaches store shelves, it must undergo a lot of screening and inspection to ensure that buyers only get high-quality and safe food products. This is particularly important because of the risk of infections, illnesses, and allergies contracted from contaminated food.

In the United States alone, roughly one in six Americans get sick each year because of foodborne illnesses caused by pathogens and other substances. The most common pathogen that could get into food during manufacturing and distribution is Salmonella. Although Salmonella infection can be treated, its symptoms can lead to severe dehydration and death, especially for a particular strain found in ground turkey in 2011 that has become antibiotic-resistant and infected people in 34 states in the US.

Salmonella is a type of bacteria that can cause stomach pain, fever, and diarrhea. It’s typically found in raw and undercooked eggs and meat, unpasteurized milk and dairy products, raw fruits and vegetables, and processed food like peanut butter and packaged meat.

In addition to pathogens, other substances can contact food during production, such as metal, stones, glass, and plastic. These foreign particles may cause lacerations in the internal organs and bowel obstruction when ingested. Because of these food contamination issues, several food manufacturing companies and fast-food chains have filed for bankruptcy and closed down.

If you’re a food entrepreneur, you should carefully choose and implement an inspection system that will help you ensure the delivery of safe and high-quality food products to your consumers. You should also consider working with reputable professionals such as TDI Packsys inspection systems who can guide you throughout the process. To get you started, here’s a guide to help you choose the best food inspection system for your food business:

Table of Contents

Food Metal Detectors

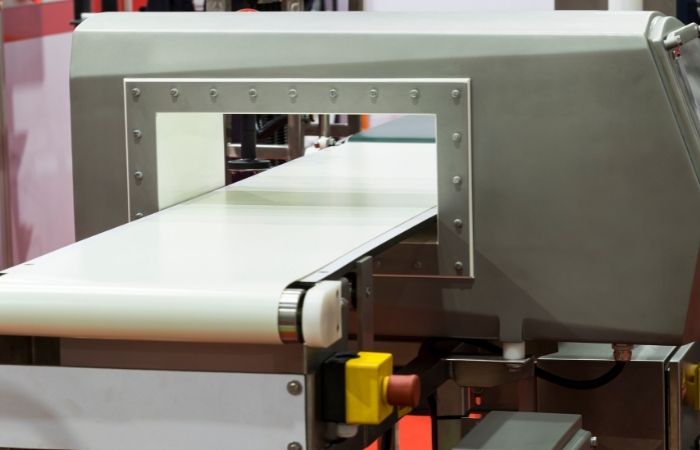

One can never tell what accident can happen onsite during production. Even a tiny innocent action can lead to a mishap, say a lightweight staple wire flying its way towards a dough getting mixed. You can avoid incidents like this and the distraught explaining how this could happen when you have reliable equipment like a food metal detector in your production line.

This equipment can detect ferrous and non-ferrous metals on bakery items, meat products, spices, and even sugar. The equipment works by analyzing the magnetic field in the inspection zone, ensuring no metal will be present in the products that you’ll distribute to your market.

Vision Systems

Food presentation and aesthetics are also vital components in the food business. With the proliferation of social media comes selfies and product shots uploaded every second of every day. Keep in mind that a botched appearance of a food product displayed on social media feeds may turn off many potential customers.

Vision systems provide a solution by scanning packaging for defects and irregularities, ensuring that labels and stickers are aligned and fill lines are up to par. It also checks if barcodes are accurate and labels are printed legibly.

X-ray Inspection Systems

Aside from metallic contaminants, an x-ray inspection system can also detect non-metals like sticks, plastic, bone, and glass. It can also detect defects in packaging like breakage, cracks, and displacement. Displaced and improperly screwed bottle caps are highly susceptible to getting contaminated and can cause foodborne illnesses. Hence, having a piece of highly dependable equipment like an x-ray inspection system can speed up the production line without sacrificing quality.

Checkweighers

Compliance with weight accuracy is essential in the food business. It won’t just ensure that your consumers are satisfied with the product they’re paying for but will also guarantee your profitability in the long run.

Checkweighers reject any underweight or overweight item in the production line fast and efficiently. This will ensure that your business adheres to regulations and your consumers won’t feel shortchanged.

Color Sorters

You might be wondering how all raisins in a package look almost exactly alike, and no piece with a different shade gets mixed in. Or a factory that manufactures both black and green olives can ensure accuracy in their dispatched products. They do this with the help of color sorters.

This equipment uses high-tech optical sensors that can recognize even the slightest chromatic difference in the items passing through the chute. It’s highly utilized by food businesses that process rice, grains, herbs, and sugar.

Conclusion

Taking extra steps to guarantee the safety and satisfaction of your consumers will be a significant investment that will enable you to reap rewards and increase your bottom line eventually. Remember that you don’t gain consumer trust overnight. You’ll have to work hard for it, and it will show in the consistency and quality of the products you put on the market.