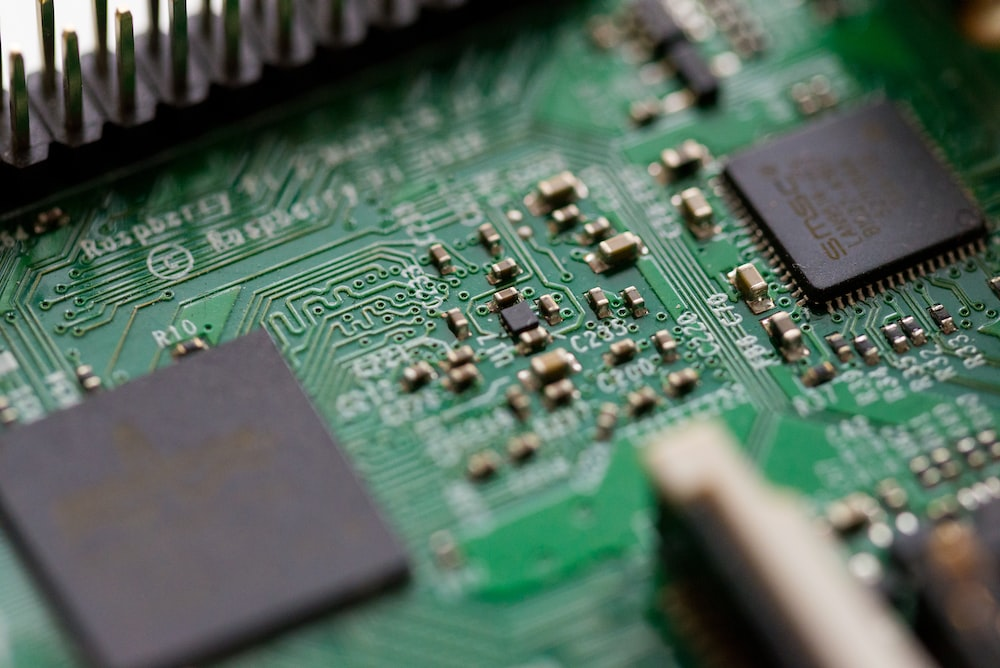

PCB (printed circuit board), also known as the brain of electronics, plays a crucial role in implementing electronic products & functions. The PCB board tells electricity where to run and how Connect electronic components to the circuit board and other parts of electronic products.

Even though modern technology constantly evolves, circuit boards are gradually becoming smaller. However, circuit boards remain highly reliable and multifunctional despite their diminutive size. So, PCB service still covers many different things, each affecting how smoothly or successfully a PCB board runs.

Due to its abundance of natural and human resources, favorable national policies, stable political environment, and ever-increasing international influence, China is unquestionably one of the most dynamic economies in the world. Nevertheless, this eastern nation with a long and storied past appears slightly different from what people have imagined, usually where misunderstandings arise. As a result, global customers must gain a deeper understanding of & quot; Chinese.

characteristics& amp; quot;

Regarding China PCB service to better utilize China & amp;#39;s resources that contribute to high-quality electronics manufacturing for essential benefit achievement dependent on electronic products.

Principals of PCB Service Despite its small size, the complexities of its uprising mean that the PCB board still involves many, if not many, aspects. The most critical elements of PCB service are:

1) PCB Design The PCB service begins with a concept expressed in a PCB design file. PCB manufacturers receive detailed information from the circuit board design file regarding the PCBs final appearance.

2) The PCB design file should include fundamental parameters like layer count, copper weight, board-to-board interconnection, silkscreen, and solder mask, among others.

3) PCB Prototyping A PCB prototype is a straightforward method for determining whether a PCB design file is correct and is a valuable reference before mass production. Lead time and quality are the most critical aspects of PCB service for prototype PCBs, and the first is even more critical. Genuine PCBs can begin as long as the prototype PCB is approved.

4) Fabrication The primary component of PCB service, PCB fabrication provides a solid foundation for electronic connection. PCBs are made by adhering to a professional PCB manufacturing process consisting of several steps that must be improved to meet the market 's ever-changing needs.

5) PCB Assembly Component sourcing is implemented simultaneously with PCB assembly, which occurs after PCB fabrication. With components participating in PCB service, PCB assembly further expands the PCB board 's connection range. SMT (surface mount technology) assembly, an automated manufacturing line with high assembly efficiency, is currently the most common type of PCB assembly.

6) PCB Rework and Repair A subset of PCB service is PCB rework. After all, high-quality PCBs do not require any additional work or maintenance.

7) PCB Sourcing The term & quot; PCB sourcing & ;quot; refers to a wide range of PCB service activities, including the acquisition of components, copper foil, and substrate materials, among other things. In addition, it is an easy way to connect customers and manufacturers.

Some Helpful Hints for Getting the Best PCB Service from China It is essential to acknowledge that getting PCB service from China could be better. When prices are low, customers will always fall into some& amp; quot; traps & quot. If you concentrate more on the qualification issues that China PCB manufacturers or assemblers face, you can altogether avoid the traps:

1) When PCB manufacturers in China are certified by ISO9001, UL, RoHS, etc., they are more dependable. Regarding quality or manufacturing technology.

2) China PCB manufacturers are more trustworthy when they have their factory and invite you to visit it.

3) When they offer you continuous follow-up service, China PCB manufacturers are more dependable.

4) China PCB manufacturers are more reliable when they have been in business for a considerable time.

There are a lot of these tips for getting the best PCB service from China, and each customer sticks to his or her evaluation criteria to determine which PCB service is best. view more